Phau Ntawv Qhia Txog Kev Xaiv thiab Kev Siv Lub Tshuab Thermoforming Pwm

I. Kev Taw Qhia

Thermoforming thev naus laus zis tab tom muaj kev loj hlob zoo hauv kev lag luam yas niaj hnub no, nrog rau kev xaiv thiab siv cov pwm ua qhov tseem ceeb hauv kev txiav txim siab ntau lawm. Kab lus no delves rau hauv cov nuanced yam ntawm thermoforming tshuab pwm xaiv thiab siv, muab rau koj nrog cov lus qhia dav. Los ntawm qhov sib txawv ntawm cov pwm hlau nrog cov pwm polymer mus rau kev xaiv ntawm ib kab noj hniav thiab ntau kab noj hniav pwm, peb nthuav tawm cov kev txiav txim siab tom qab txhua qhov kev txiav txim.

II. Txheej txheem cej luam ntawm Thermoforming Technology

Nyob rau hauv lub realm ntawm yas tsim, pwm tshwm sim raws li pivotal Cheebtsam, dictating lub meej contours thiab qhov ntev ntawm cov khoom kawg. Pwm ua si ob lub luag haujlwm: ua kom yooj yim rau cov txheej txheem shaping thiab ua kom muaj kev sib luag ntawm cov khoom tsim. Txawm hais tias crafted los ntawm cov hlau los yog polymers, cov pwm no pab txhawb qhov zoo thiab sib xws ntawm cov khoom siv thermoformed. Ntu ntu no tshawb txog qhov tseem ceeb ntawm cov pwm hauv cov yas shaping, sib piv qhov zoo thiab kev siv cov hlau thiab polymer pwm. Ntxiv mus, nws delves rau hauv kev txiav txim siab koom nrog hauv kev xaiv ntawm ib leeg-kab noj hniav thiab ntau kab noj hniav pwm, elucidating lawv cov kev cuam tshuam rau kev tsim khoom thiab kev siv nyiaj.

Cov toj roob hauv pes thermoforming txuas ntxiv hloov zuj zus, cuam tshuam los ntawm kev nce qib thev naus laus zis thiab kev lag luam xav tau. Hauv seem no, peb txheeb xyuas cov xwm txheej tam sim no tsim cov kev lag luam thermoforming thiab cov kev xav tau uas lawv tsim. Los ntawm kev sib koom ua ke ntawm cov thev naus laus zis thev naus laus zis mus rau kev tsom mus rau kev coj ua hauv eco-friendly, kev nkag siab txog cov qauv no yog qhov tseem ceeb rau kev ua raws li kev lag luam kev loj hlob. Kev pom rau hauv lub xeev tam sim no thiab yav tom ntej kev kwv yees muab kev pom dav dav ntawm cov thermoforming sector, pab cov kws tshaj lij hauv kev ua raws li lawv cov kev coj ua nrog cov kev xav tau tshiab.

III. Hom Thermoforming Tshuab Moulds

A. Hlau Moulds vs. Polymer Moulds:

Sib piv kev soj ntsuam ntawm qhov zoo thiab qhov tsis zoo

Hlau pwm thiab polymer pwm sawv cev rau ob qho kev xaiv sib txawv hauv thermoforming, txhua tus nrog nws cov txheej txheem zoo thiab qhov tsis zoo. Hlau pwm, feem ntau crafted los ntawm txhuas los yog hlau, khav theeb durability thiab precision, kom ntseeg tau siv ntev thiab zoo tso zis. Ntawm qhov ntxeev sab, lawv cov nqi tsim khoom thiab qhov hnyav tuaj yeem ua rau muaj kev txwv. Nyob rau hauv sib piv, polymer pwm, feem ntau muaj xws li cov ntaub ntawv xws li epoxy los yog composite resins, muab nqi-zoo thiab sib zog. Txawm li cas los xij, lawv tuaj yeem pom tsawg dua qhov ntev thiab qhov tseeb piv rau lawv cov khoom siv hlau. Cov ntu ntu no ua tiav kev soj ntsuam zoo ntawm qhov zoo thiab qhov tsis zoo cuam tshuam nrog cov hlau thiab polymer pwm, pab cov tuam txhab ua cov kev txiav txim siab raws li lawv cov kev xav tau tshwj xeeb.

Daim ntawv thov tsim nyog rau cov khoom sib txawv

Qhov tsim nyog ntawm cov hlau los yog polymer pwm yog nyob ntawm daim ntawv thov tshwj xeeb hauv cov txheej txheem thermoforming. Hlau pwm ci nyob rau hauv cov xwm txheej uas xav tau cov ntsiab lus tsis sib xws, nruj kam rau ua, thiab txuas ntxiv kev tsim khoom. Conversely, polymer pwm pom lawv niche nyob rau hauv tej yaam num nrog qis ntau lawm, tso cai rau ib tug sib npaug ntawm tus nqi efficiency thiab tau zoo. Los ntawm kev tshawb nrhiav cov yam ntxwv sib txawv thiab cov kev siv zoo tshaj plaws ntawm cov ntaub ntawv pwm no, ntu no qhia cov tuam txhab rau kev xaiv kom zoo raws li lawv cov hom phiaj tsim khoom.

B. Tib-Cavity Moulds vs. Multi-Cavity Pwm

Kev txiav txim siab ntawm Kev Ua Tau Zoo thiab Tus Nqi

Qhov kev txiav txim siab ntawm ib leeg-kab noj hniav thiab ntau kab noj hniav pwm cuam tshuam rau kev ua tau zoo thiab tus nqi-zoo ntawm cov txheej txheem thermoforming. Ib leeg-cav pwm pwm, ua ib yam khoom ib zaug, muab kev yooj yim thiab yooj yim ntawm kev tswj tab sis tej zaum yuav lag nyob rau hauv tag nrho cov khoom ceev. Ntawm qhov tod tes, ntau cov kab noj hniav tuaj yeem ua rau tib lub sijhawm tsim ntawm ntau yam khoom, txhim kho tus nqi ntau lawm tab sis xav tau kev teeb tsa ntau dua. Cov kab lus no ua cov ncauj lus kom ntxaws txog kev tsim khoom thiab cov nqi cuam tshuam ntawm ob hom pwm, txhawb nqa cov tuam txhab tsim cov kev xaiv xaiv raws li lawv qhov ntau lawm thiab cov kev xav tau.

Xaiv hom pwm tsim nyog

Kev xaiv ntawm ib kab noj hniav thiab ntau kab noj hniav yuav tsum muaj kev nkag siab zoo txog kev xav tau ntau lawm. Cov khoom xws li kev txiav txim kom muaj nuj nqis, qhov xav tau ceev ceev, thiab cov peev txheej muaj nyob hauv lub luag haujlwm tseem ceeb hauv txoj kev txiav txim siab no. Los ntawm kev muab kev nkag siab txog cov kev xav tau koom nrog, ntu no pab cov tuam txhab xaiv cov pwm uas zoo tshaj plaws rau lawv cov hom phiaj kev ua haujlwm thiab kev txwv nyiaj txiag.

IV. Cov ntsiab lus tseem ceeb hauv kev xaiv pwm

Cov khoom xaiv thiab Durability

Xaiv cov khoom tsim nyog rau pwm yog qhov tseem ceeb hauv kev ua kom lawv lub neej ntev thiab kev ua haujlwm. Nyob rau hauv cov ntsiab lus no, kev siv ntawm 6061 alloy txhuas daim hlau sawv tawm rau nws cov yam ntxwv zoo kawg li. Lub cev muaj zog thiab hnav tsis kam ntawm cov hlau no ua rau lub zog ntawm cov pwm, tso cai rau lawv tiv taus qhov xav tau ntawm cov txheej txheem thermoforming. Tsis tas li ntawd, kev tiv thaiv corrosion ntawm alloy aluminium ntxiv txhim khu kev ruaj ntseg ntawm cov pwm, ua rau lawv haum rau kev siv ntev thiab siv zog.

Tsim thiab Precision Requirements

Kev tsim cov pwm ua lub luag haujlwm tseem ceeb hauv kev ua tiav qhov xav tau precision hauv thermoforming. Thaum xaiv 6061 alloy aluminium daim hlau, lawv qhov tshwj xeeb machinability yooj yim rau kev tsim cov pwm tsim nrog kev ua haujlwm siab. Kev muaj peev xwm ua tau zoo rau kev ua siab ntev thiab cov ntsiab lus sib txawv ua kom cov pwm ua tau raws li cov lus qhia meej uas yuav tsum tau ua rau kev tsim cov khoom yas zoo tshaj plaws. Ntu ntu no tshawb txog qhov kev sib raug zoo ntawm cov pwm tsim thiab qhov tseeb, hais txog yuav ua li cas 6061 alloy aluminium txhawb qhov kev ua tiav ntawm cov txheej txheem pwm thiab meej.

Tus nqi thiab ntau lawm Efficiency Trade-offs

Sib npaug cov nqi thiab kev ua haujlwm ntau lawm yog qhov tseem ceeb hauv kev xaiv pwm. Thaum 6061 alloy aluminium daim hlau tuaj yeem koom nrog kev nqis peev thawj zaug, lawv cov txiaj ntsig zoo nyob rau lub sijhawm ntev yuav tsum xav txog. Lub teeb yuag ntawm aluminium txo qhov hnyav tag nrho ntawm cov pwm, uas ua rau kev txuag hluav taws xob thiab txhim kho kev ua haujlwm zoo. Ntxiv mus, qhov yooj yim ntawm machining aluminium pab ua kom cov txheej txheem ntau lawm, cuam tshuam rau tag nrho cov nqi-zoo. Tshooj lus no nthuav tawm cov kev lag luam tawm ntawm cov nqi thiab kev tsim khoom, muab kev nkag siab txog yuav ua li cas xaiv cov khoom siv pwm, tshwj xeeb tshaj yog 6061 alloy aluminium, tuaj yeem cuam tshuam rau kev lag luam ntawm kev ua haujlwm thermoforming.

V. Kev xyaum thiab kev sib qhia

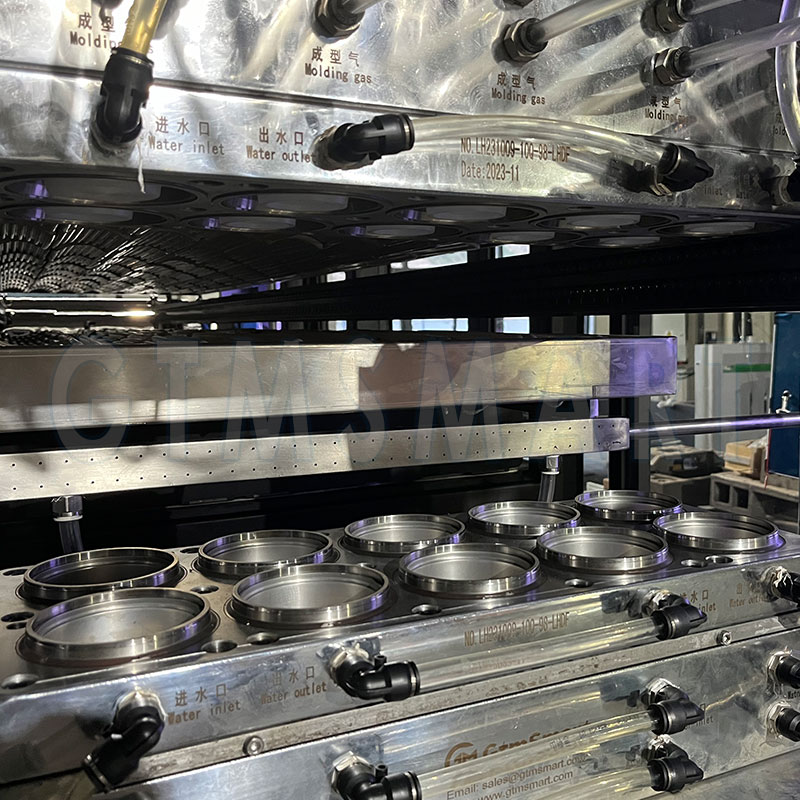

Nyob rau hauv lub realm ntawm thermoforming, GtmSmartDisposable Cup Forming Tshuab stands raws li ib tug noteworthy ntaub ntawv kawm, tshwj xeeb tshaj yog nyob rau hauv nws cov kev xaiv ntawm cov ntaub ntawv pwm. Cov pwm ua hauj lwm feem ntau siv 6061 alloy txhuas daim hlau. Qhov kev txiav txim siab xaiv no yog tsav los ntawm lub siab xav siv cov txiaj ntsig sib txawv uas tau muab los ntawm cov aluminium alloy no nyob rau hauv ib puag ncig ntawm cov khob ntim khoom pov tseg.

Kev tshuaj xyuas ntawm Cov Nta Tseem Ceeb

Daim ntawv thov ntawm 6061 alloy txhuas daim hlau nyob rau hauv lubyas khob thermoforming tshuabmoulds nthuav tawm ntau yam tseem ceeb:

1. Durability thiab Longevity: Lub zog muaj zog ntawm 6061 alloy aluminium ua kom lub zog ntawm cov pwm, tso cai rau lawv tuaj yeem tiv taus cov cua sov rov ua dua thiab tsim cov voj voog uas cuam tshuam nrog cov khoom ntim ntau ntawm cov khob pov tseg. Qhov tsis kam hnav thiab tsim kua muag ua rau lub neej ntev pwm thiab cov khoom zoo ib yam.

2. Precision hauv khob tsim: Qhov tshwj xeeb machinability ntawm 6061 alloy aluminium pab txhawb kev tsim cov pwm nrog cov qauv tsim thiab cov ntsiab lus meej. Qhov kev txiav txim siab no yog qhov tseem ceeb hauv kev ua kom muaj kev sib haum xeeb thoob plaws lub khob tsim, ua tau raws li cov qauv zoo uas xav tau hauv kev lag luam khob pov tseg.

3. Tus nqi tsim khoom: Thaum thawj zaug peev hauv 6061 alloy aluminium daim hlau yuav siab dua, qhov kev siv nyiaj mus sij hawm ntev yuav tshwm sim. Lub teeb yuag ntawm aluminium txo qhov hnyav tag nrho ntawm cov pwm, uas ua rau kev txuag hluav taws xob thiab txhim kho kev ua haujlwm zoo. Qhov yooj yim ntawm machining aluminium kuj tseem txhawb nqa cov txheej txheem ntau lawm, optimizing tus nqi-zoo ntawm Smart Disposable Cup Forming Machine.

Cov ntaub ntawv kawm no ua piv txwv li kev xaiv xaiv cov khoom siv pwm, xws li 6061 alloy aluminium, tuaj yeem cuam tshuam qhov kev ua tau zoo, ua haujlwm ntev, thiab tus nqi-zoo ntawm cov txheej txheem thermoforming hauv kev siv tiag tiag.

Xaus

Hauv kev xaus, kev tshawb fawb dav dav ntawm thermoforming thev naus laus zis, hom pwm, thiab cov kev xav tseem ceeb hauv kev xaiv pwm underscores intricate interplay ntawm yam shaping lub yas manufacturing toj roob hauv pes. Kev siv ntawm 6061 alloy aluminium daim hlau ua cov khoom pwm tseem ceeb tshwm sim raws li kev txiav txim siab, muab qhov sib npaug ntawm qhov ua tau zoo, kev ua tau zoo, thiab kev siv nyiaj zoo. Cov ntaub ntawv kawm ntawm GtmSmartyas khob txoj kev tshuabua piv txwv qhov cuam tshuam rau qhov kev xaiv ntawm cov khoom siv no, qhia tias nws ua rau lub tshuab ua haujlwm zoo, ua haujlwm ntev, thiab tsim cov khob ntim khoom zoo.

Post lub sij hawm: Dec-18-2023