Dab tsi yog Cov Ntsiab Cai Ua Haujlwm ntawm Lub Qe Tais Nqus Tsev Ua Tshuab

Taw qhia

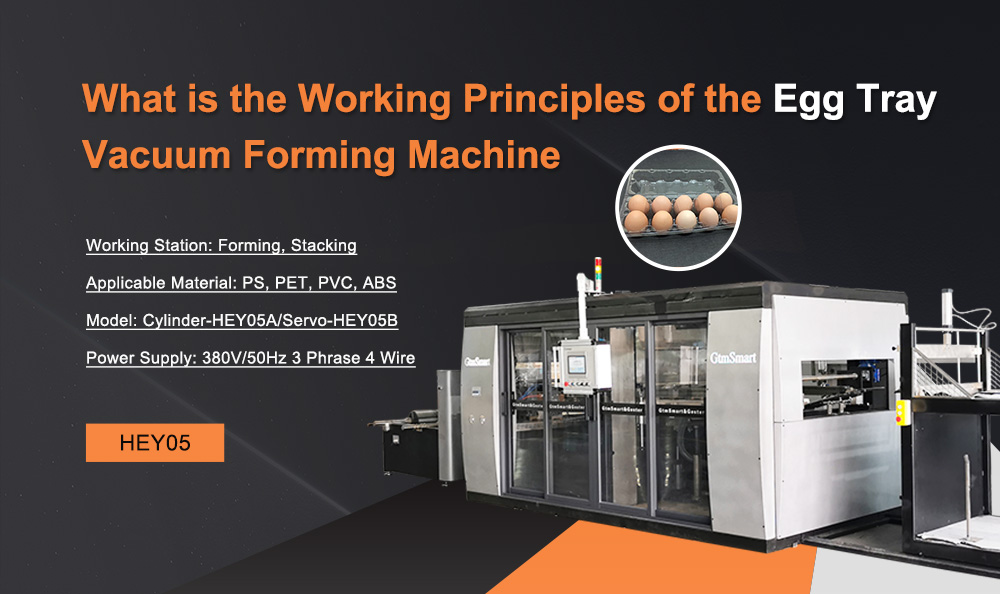

Qe ntim tau los ntev heev nyob rau hauv cov nqe lus ntawm innovation thiab sustainability. Ib qho kev nce qib tseem ceeb tshaj plaws hauv kev lag luam no yog qhovQe Tray Nqus Tshuab Ua Tshuab . Nyob rau hauv tsab xov xwm no, peb yuav delve rau hauv intricate cov ntsiab lus ntawm yuav ua li cas lub tshuab no ua hauj lwm, muab ib tug kev nkag siab ntawm nws functionality.

Kev piav qhia ntawm Lub Tshuab Nqus Tsev

Vacuum forming, tseem hu ua thermoforming, lub tshuab nqus tsev siab, los yog lub tshuab nqus tsev molding, yog cov txheej txheem tsim khoom siv los tsim cov khoom yas rau hauv ntau hom. Cov txheej txheem no tso siab rau cov hauv paus ntsiab lus ntawm cov cua sov thiab lub tshuab nqus tsev los tsim cov qauv tsim thiab cov qauv sib txawv. Lub tshuab nqus tsev thermal lub tshuab ua raws li cov txheej txheem no los tsim cov qe qe tais kom zoo thiab eco-friendly.

Khoom zoo

-PLC Tswj System: Lub plawv ntawm Egg Tray Vacuum Forming Machine yog nws PLC tswj qhov system. Qhov kev siv thev naus laus zis no ua kom muaj kev ruaj ntseg thiab ua tiav thoob plaws hauv cov txheej txheem tsim khoom. Los ntawm kev ua haujlwm servo drives rau sab sauv thiab qis pwm daim hlau thiab servo noj, lub tshuab tau lees paub zoo thiab txhim khu kev qha.

-Human-Computer Interface:Covyas nqus tsev thermal forming tshuab nta lub siab-txhais kov-screen tib neeg-lub computer interface uas muaj kev saib xyuas lub sijhawm ntawm txhua qhov kev teeb tsa. Qhov no tso cai rau cov neeg ua haujlwm saib xyuas tag nrho cov haujlwm, kom ntseeg tau tias lub tshuab ua haujlwm zoo.

-Self-Diagnosis Function: Txhawm rau ua haujlwm thiab kev saib xyuas kom yooj yim dua, lub tshuab nqus tsev lub tshuab nqus tsev yog nruab nrog kev kuaj xyuas tus kheej. Qhov no feature muab cov ntaub ntawv hais txog kev puas tsuaj ntawm lub sijhawm, ua rau nws yooj yim rau cov tswv lag luam los daws cov teeb meem sai sai thiab ua tau zoo.

-Khoom Parameter Cia:Covautomated nqus tsev sib sau tshuab yog tsim los khaws ntau yam khoom parameter. Lub peev xwm khaws cia no ua rau cov txheej txheem ntau lawm thaum hloov ntawm cov khoom sib txawv. Debugging thiab reconfiguration ua sai thiab hassle-dawb.

qe tais lub tshuab nqus tsev sib sau tshuab

Chaw Ua Haujlwm Chaw Ua Haujlwm: Tsim thiab Stacking

Qhov chaw ua hauj lwm ntawm Lub Tshuab Nqus Tsev Lub Tshuab Nqus Tsev yog muab faib ua ob theem tseem ceeb: kev tsim thiab stacking. Cia peb tshawb nrhiav cov ntsiab cai ua haujlwm ntawm txhua theem no.

1. Kev tsim:

| Cua sov: | Cov txheej txheem pib los ntawm cua sov ib daim ntawv yas rau nws qhov zoo tshaj plaws tsim kub. Qhov kub thiab txias no yuav txawv nyob ntawm seb hom yas siv. |

| Pwm qhov chaw: | Cov ntawv yas rhuab yog muab tso rau nruab nrab ntawm cov pwm sab saud thiab qis. Cov pwm no tau tsim tshwj xeeb kom haum rau cov duab ntawm lub qe tais. |

| Vacuum Application: | Thaum cov ntawv yas nyob rau hauv qhov chaw, lub tshuab nqus tsev yog siv rau hauv qab, tsim suction. Qhov suction no rub cov yas rhuab mus rau hauv pwm kab noj hniav, zoo tsim lub qe tais zoo. |

| Cua txias: | Tom qab cov txheej txheem tsim, cov pwm yog txias kom khov cov yas rau hauv nws qhov kev xav tau. Cov kauj ruam no yog qhov tseem ceeb rau kev tswj kom muaj kev ncaj ncees. |

Tsim Chaw Nres Tsheb

2. stacking:

| Qe Tais Tso Tawm: | Thaum cov qe tais tau coj lawv cov duab, lawv ua tib zoo tso tawm ntawm cov pwm. |

| stacking: | Cov tais qe tsim tau muab tso ua ke, feem ntau nyob hauv kab, los npaj lawv rau kev ua ntxiv lossis ntim khoom. |

Stacking chaw nres tsheb

Xaus

CovQe Tray Nqus Tshuab Ua Tshuab yog kev siv lub tshuab nqus tsev tsim, ua ke nrog nws cov yam ntxwv siab heev xws li PLC tswj qhov system, tib neeg-khoos phis tawj interface, kev kuaj tus kheej muaj nuj nqi, thiab qhov ntsuas ntsuas, xyuas kom meej thiab zoo ib yam. Kev nkag siab txog cov qauv kev ua haujlwm ntawm lub tshuab no ua rau pom qhov kev tsim kho tshiab uas tsav lub qe ntim kev lag luam rau kev ruaj khov thiab ua haujlwm tau zoo.

Post lub sij hawm: Oct-19-2023